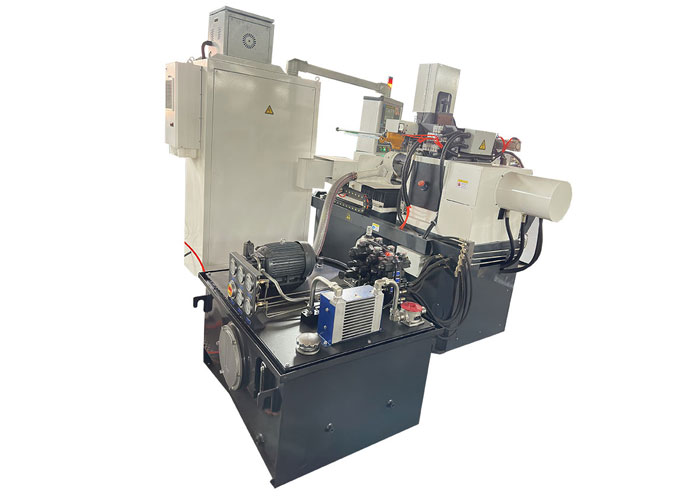

DX15-6自动内圆车

DX15-6 Automatic ID boring machine

DX15-6自动内圆车

The applicationand feature of the machine

用途及特点

本机床是一种新开发用于加工活塞环内圆的产品,。完全由数控系统控制,并实现自动装卸料。它能有效地车削各种内圆面,如圆弧槽、内倒角、内台阶等。由于采用了数控和交流伺服驱动单元,环件的内圆加工可以获得良好的粗糙度和形状精度。

This machine tool is a newly developed product designed for machining the inner circle of piston rings. Fully controlled by a CNC system, it achieves automatic loading and unloading. It can effectively turn various inner circular surfaces, such as arc grooves, inner chamfers, and inner steps. Thanks to the adoption of CNC technology and AC servo drive units, the inner circle machining of ring workpieces can achieve excellent surface roughness and shape accuracy.

机床的加工、上下料循环由程序执行。主轴电机采用变频控制,实现无级调速。进给速度和切削深度可以通过系统中的变量来设定。装料机构为液压驱动, 料架水平布置,卸料由机械爪完成。机床具有较高的定位精度、报警显示、自诊断功能和可靠性。

The machining, loading, and unloading cycles of the machine tool are executed by programs. The spindle motor adopts frequency conversion control to realize stepless speed regulation. The feed rate and cutting depth can be set through variables in the system. The feeding mechanism is hydraulically driven with a horizontally arranged material rack, and unloading is completed by a mechanical claw. The machine tool features high positioning accuracy, alarm display, self-diagnostic function, and reliable performance.

Technical parameters:

技术参数

|

Process diameter /加工环径 |

Φ 65mm- Φ 130mm |

|

Main spindle motor with gearbox /主轴减速电机 Main spindle servo motor with gearbox(optional) /主轴伺服电机带减速机(选配) |

380V/5.5KW with R67 gearbox /R67减速机 βiI 8/12000-B(optional) |

|

X axis servo motor / X轴伺服电机 |

βis 12/2000 |

|

Z axis servo motor / Z轴伺服电机 |

βis 12/2000 |

|

Stack length /装夹长度 |

MAX: 25 mm |

|

Hydraulic pump motor /液压泵电机 |

3KW/380V/1440rpm |

|

Overall size /外形尺寸 |

2600×1600×2500 mm |

|

N/W /净重 |

2200kg |